The power transmission products are designed in the USA, manufactured in the European Union and qualification based on Lean Six Sigma solutions. Through the delivery of professional engineering design, we create expanded applications for machined and molded products, and offer cost and time savings to our customers. Our engineering team provides structural analysis, gear mesh optimizations and creates professional certified gearbox drawings. Our clients may create their own documentation based on our engineering drive train design support or use their own preferred tool supplier, realizing additional cost saving.

MoldedGear LLC has innovative and over 25 years of experience of gearing to optimize the performance of molded polymers, those resulting improved gears that are stronger, quieter, lighter, and more efficient than traditional plastic gears. Our engineering team has a strong understanding of plastic and powder metal gear design. The material selection uses scientific principles to robust respectable design.

Our engineering team has a strong understanding of plastic and powder metal gear design. Improved and optimized gears are stronger, quieter, lighter, and more efficient than traditional standard gears.

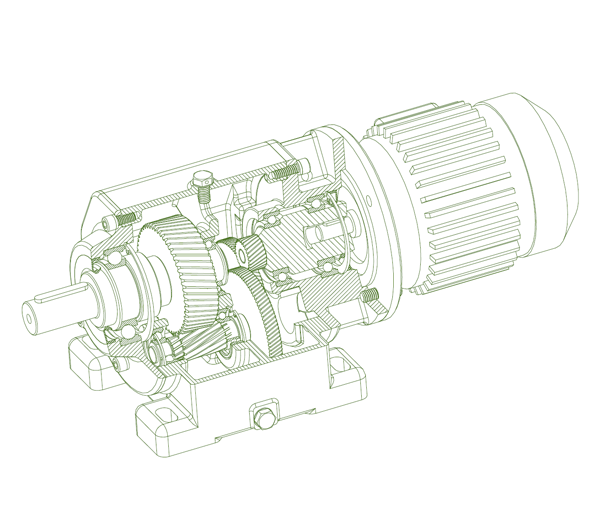

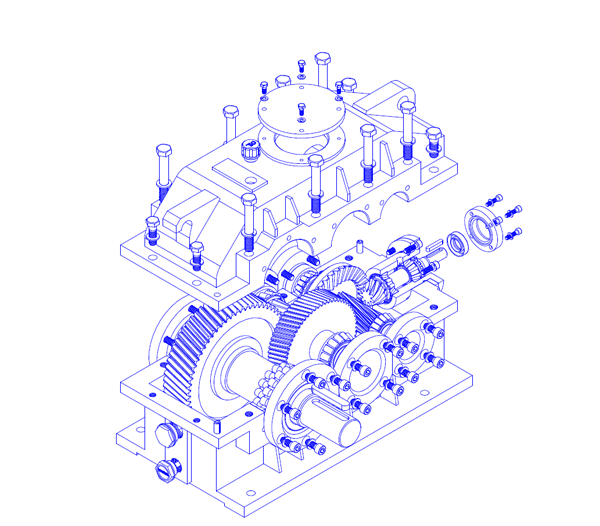

Standard Gearboxes come in a wide range of load capacities. Specify the speed reduction and shaft configurations from our standard gearboxes and we customize them to meet your application needs.

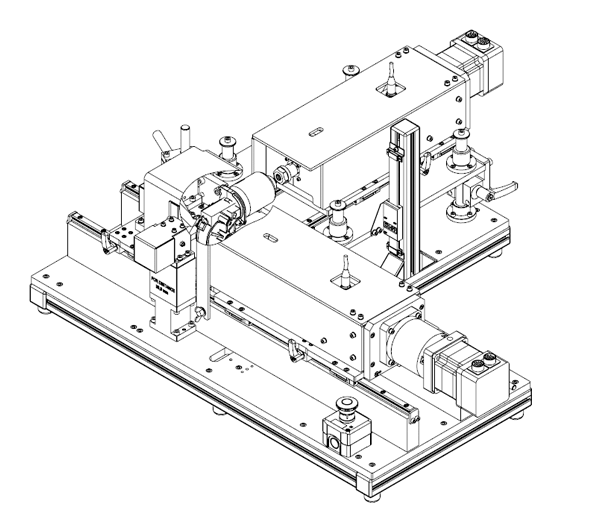

It is summarized below the type of testing that we usually perform for gearbox qualification and proof testing.

It is summarized below the type of testing that we usually perform for gearbox qualification and proof testing. The gearbox optimization and productivity require application load case or load spectra measurement. The structural analysis includes gear meshes, shafts, and bearings, housing and lubrication optimization. After prototyping the gearbox testing should be performed on automated gear tester rig. Several important tests are required in our lab in order to validate the product.

More information about Gearbox Proof TestingPlease fill in our form in connection with your order! After that, our colleagues will contact you.

E-mail address:

info@moldedgear.com

Phone

+1 202 470 6030