Gearbox Manufacturing, Repairing, Prototyping:

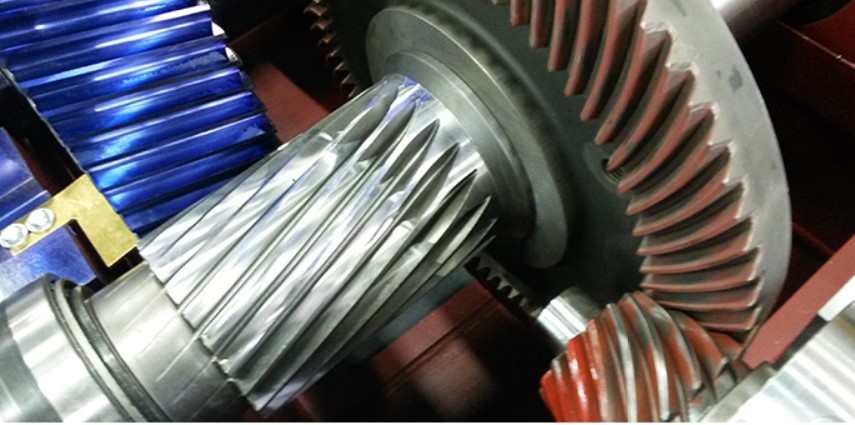

MoldedGear LLC can deliver power transmission solutions to the mining, steel, oil field, gas industries and elsewhere. Our European Union manufacturing partner features state-of-the-art gear hobbing, heat treating, grinding and quality control capabilities. With a complete offering of spur, helical, double helical, worm, bevel gearing, rack, cycloid, lantern- crown, pulleys, sprockets, splines, couplings, shaft, catalog or custom gearboxes, and also gearbox repair services.

MoldedGear LLC’s manufacturer partner in the European Union can provide high quality precision mid and small size actuator housing, gears in ferrous and non-ferrous material. Gears and components are made to special dimensions to all industries, including automotive, medical, surgical, dental, home appliance, scientific instruments, paper handling, cutting machines, and other critical engineering fields.

We specialize in fine pitch gearing, typically less than 50 inch (1000 mm) diameter. We can manufacture to your drawing, or reverse engineering from your existing product. We have machining facilities enabling us to better serve our customers by providing turning, milling, boring, facing, drilling and tapping. Quantities range from single prototype to thousands production runs. Our manufacturing process ensures competitive prices and high-quality products.