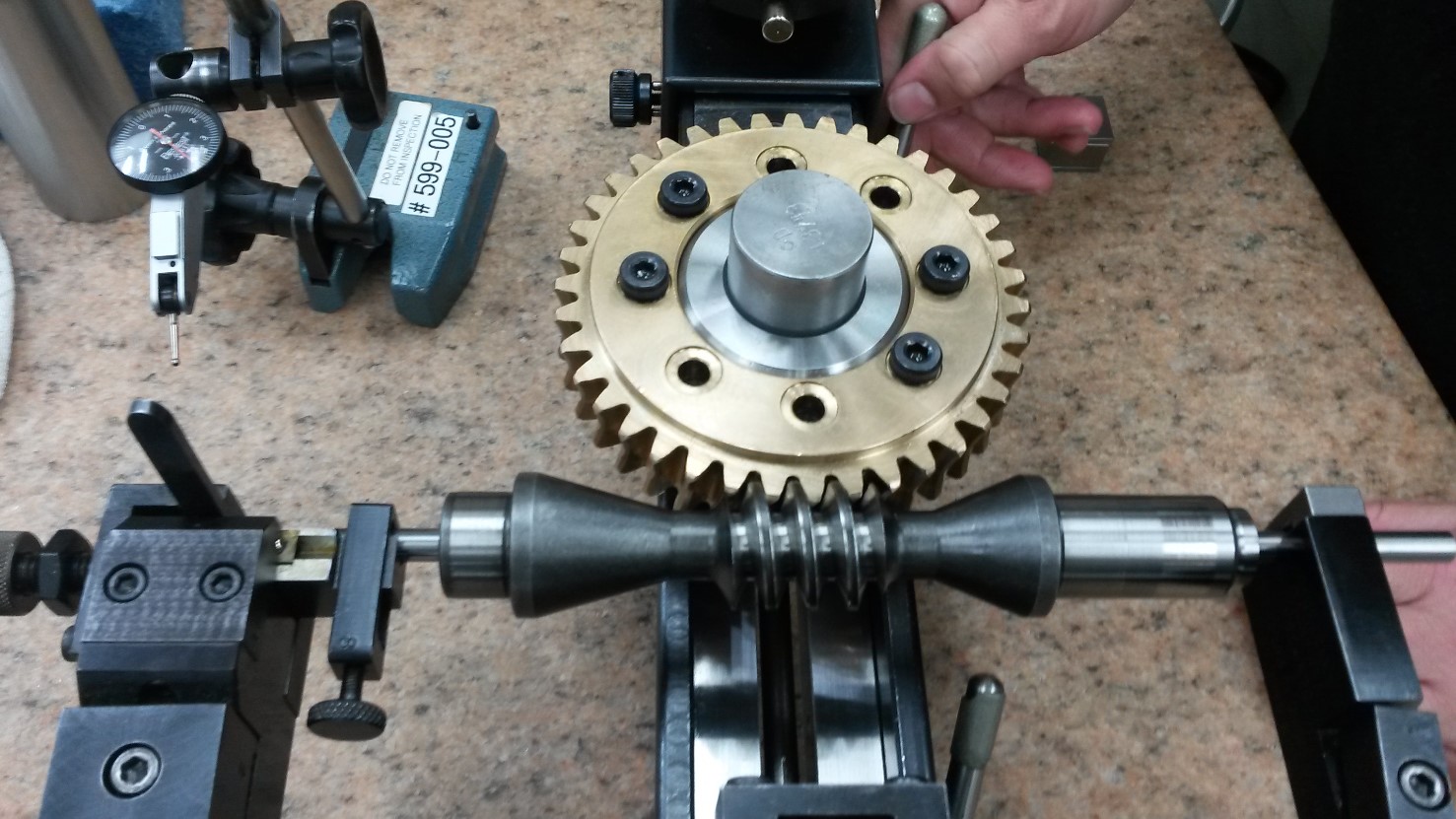

Gear Train Qualification and Testing:

We ensure quality at every step of the design and manufacturing process. Through our continuous improvement practices, we also regularly engineer and prevent non-conforming parts from getting to our customers. We also use the latest quality assurance processes in our keen testing lab to ensure that parts monitor to the highest quality standards. Total Customer Satisfaction based on implementing Lean Six Sigma Quality Management System Process.

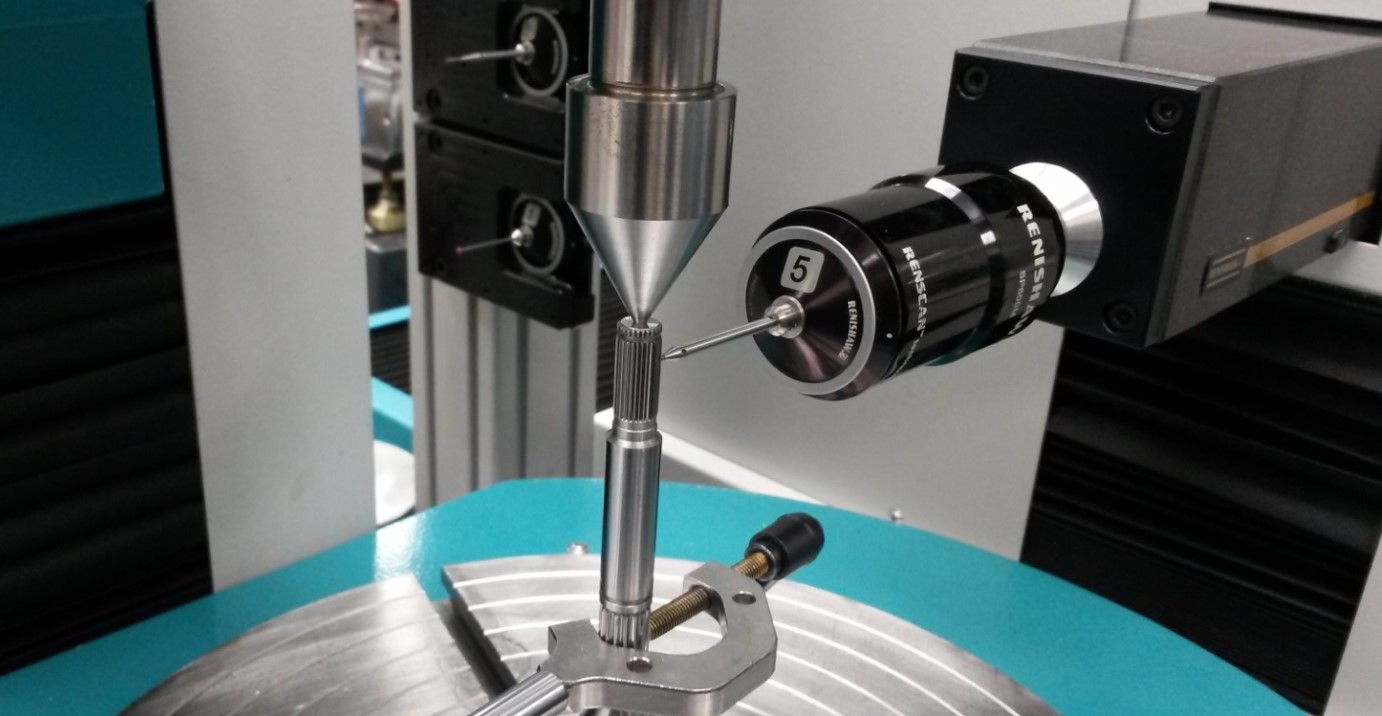

We'll provide you with engineering qualifications for the final product, guidelines for the first article inspection or statistical process control. We will develop the gear data for high volume production planes on any domestic or foreign quality standard. The documentation includes:

- Test radius master gear specification

- Measurement over 2 or 3 wires

- Span measurement over teeth

- Gear tooth profile inspection (GMM): Cumulative Pitch Deviation, Total Profile & Lead Deviation

- Tooth Wear and lubrication evaluation of porotype

- Relative noise measurement